PRODUCTS & SERVICES

Products & Services

Procurement Services

- Procurement & Supply provides a fully comprehensive procurement and supply service to our

customers mainly Oil & Gas-offshore & Cruise ship and

Marine-Ship Building. - Our scope includes strategic sourcing, material management, contract management, logistics,

which are conveniently traced with which any potential

setbacks and nonconformities are

conveniently tackled.

Products and Stock:

- Submersible Pumps, Air Diaphragm Pumps, Marine Pumps for jockey water, drill water, seawater , ballast

and etc. - Pumps monitoring and Maintenance system

- Spinning Wrench, Drill Pipe Spinner.

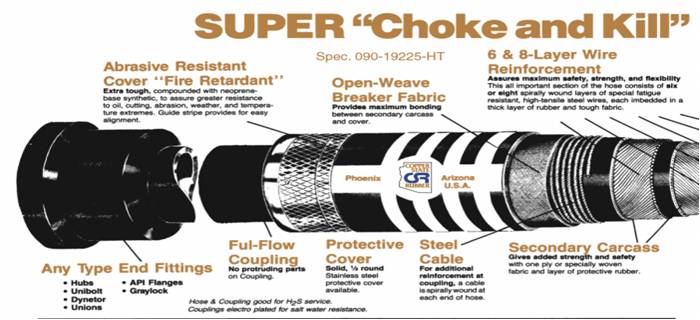

- Copper State Hoses – API 16C Choke & Kill hoses

- CWC Screens for Shale Shakers

Pumps , Valves, Hoses

- Submersible pump with Sea water construction

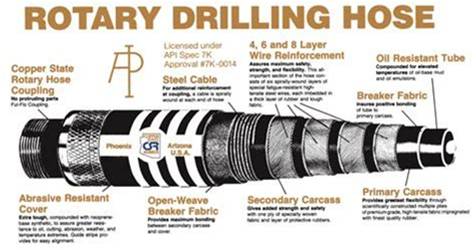

Copper State Hoses

High Pressure Oilfield Hoses

- Choke & Kill Hoses

- Cementing Hoses

- Rotary & Vibrator Hoses

- Decoking Hoses

- BOP Control Hoses

- Flexible Flow Lines

- Multi-Purpose Oilfield Service Hoses

- Hydraulic & Steam Pile Driver Hoses

Deck/Loading Oilfield Hoses

- Top Drive Blower Hose

- Fuel/Oil/Mud Transfer & OS&D Hoses

- Water Hoses

- Bulk Material Handling Hose

- Wire Braided Air Hose

- Submarine Offshore Petroleum Loading Hoses

- Submarine Hose & Sand Suction Hose

- Chemical Hoses

- Jetting Hoses

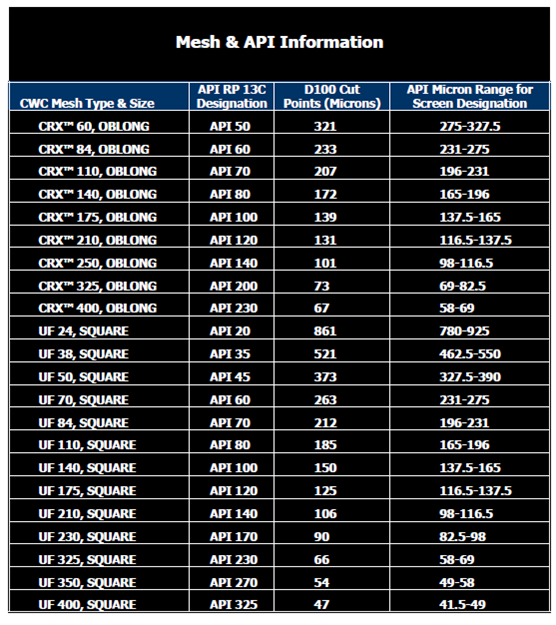

CWC Shale Shaker Screens

- Continental’s innovative CRX screens are designed for

extended longevity and increased flow while maximizing

conductance. - Cut points are on the high end of the API scale, which

means more particle removal. We use three layers of mesh

on all our CRX screens. - High grade steel frames are fabricated and welded to exact

specifications. And our specialized adhesion process gives

our product its advantage in durability. This translates into

cleaner mud, increased productivity, and a better value for

you. - API & Mesh Information

- API RP 13 C is the “recommended” way of classifying

shaker screens. Testing utilizes rotap machine and ASTM

sieves. A manufacturer’s screen samples are tested within

this sieve column. It is based on 100% retention of the

media (aluminum oxide) on the test screen for API

classification for that screen.

Pump Monitoring and maintenance system

- The pump monitoring solution tracks various performance parameters

of pumps - Benefits include managing asset ;life cycle through improved

maintenance visibility and standardize practices but not limit to: - Provides operational insight into asset performance parameters

- Informs management and operational personnel of current risks and

trends - Facilitates improvement in operational performance

- Integrates data and “Breaks Down Information Silos”

- Enables consistent and compatible methods of collection and analysis

of information - Improves transparency into corporate operational risk

- Standardises performance monitoring of assets across the corporation